- À New Wave to Fashion, À New Way of Living. Download Now on iOS Android Canada SS22

- hello@alahausse.ca

Memory Wool, Fabric tech changing on Command

Lumen Couture’s Matrix Collection and the Hopeful Solution to Fast Fashion

June 25, 2021

Third Party Ethical Certification: How to ensure a Brand is Sustainable?

June 29, 2021

Written by Chantel Ong

13 million tons of textile is wasted annually and 95% of this can still be reused or recycled. Woolmark Company’s fibre advocacy and eco-credentials program manager states: “So while wool may represent only 1.3 per cent of the global fibre supply, wool garments are donated to charity at a much higher rate of about five per cent, providing the circular potential of this garment’s lifespan.”

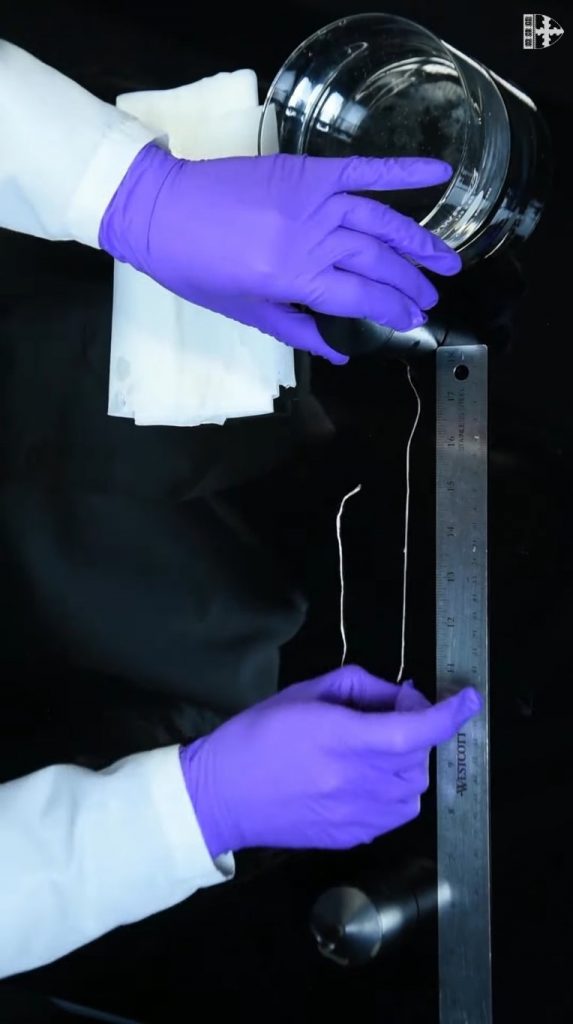

Researchers from Harvard University have developed a biodegradable and sustainable wool-like fabric tech with pre-programmed shape memory. Allowing the material to modify and hold a certain shape on command. It’s similar to the idea of having a shirt that modifies itself to fit your own specific measurements.

Shape Memory Wool

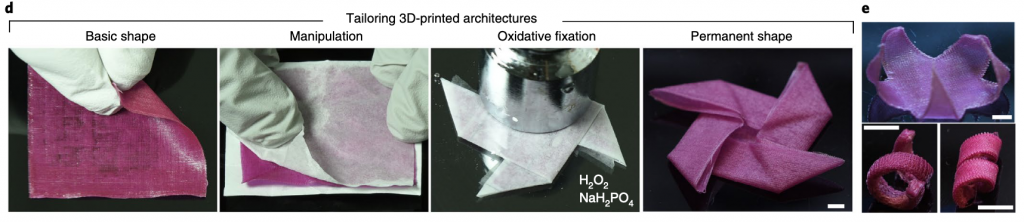

The memory wool developed by the researchers is processed into 3D fibers, similar to the human hair, it has shape memory components that is stimulated by water. The idea of shape memory is basically allowing the wool to take on both constant and adaptable shape on command, which could pave the way for more versatile garments.

Luca Cera, fellow researcher of SEAS, expounded on the specifics of the memory wool stating that: “The materials will keep the temporary shape once the stimuli are removed. If the stimuli are applied again, the material will remember the permanent shape and dynamically recover into it.”

Through the shape memory aspect of the fabric this could possibly lead to a more enhanced and customizable experience with consumers, possibly integrating itself to the sportswear and lingerie industry as they require more form-fitting specific measurements when purchasing an item.

Wool Material

This shape-shifting fabric is made by extracting keratin from recycled wool. Since keratin is a flexible bioactive polymer that can be used for advanced applications.

Luca Cera further explains how keratin is arranged into a spring-like structure known as alpha-helix. These two chains that twist together form a coiled-coil. Which are usually assembled in protofilaments and then larger fibers. The components of alpha helix and the connective chemical bonds allow the material to be both strong and a shaping activator.

Process of Memory Wool

1. Extraction

- Extract keratin from excess Angora wool used in textile manufacturing

2. Cellink’s BIO X

- Used to print the material, enabling researchers to easily visualize the structure, later adding Rhodamine B (a chemical compound and fluorescence dye) providing its magenta-like color.

3. Modelling

- After 3D printing, a star-shaped origami model is manually folded and pressed with a hydrogen peroxide solution. Allowing it to achieve permanent architecture with higher complexity

4. Shape Memory

- Fabric has shape-memory properties, researchers then folded it into a more complex origami shape for that permanent structure.

5. Conclusion

- Study found that once fabric is given water, the 3D model was malleable and could be unfolded and reshaped.

6. Dried

- When dried the shape is locked into its temporary shape

7. Revert to Original

- To revert to original water is added so that the shape is back to its original origami shape

How its works Sustainably

Through this project, they have not only discovered a new way to use recycled wool. The team believes that the implication of this project has further developed the sustainability of natural resources through recycled keratin proteins. “We could further do more for the environment than what has been done by shearing animals to this day, and through doing so, we reduce the environmental impact of the textile and fashion industry”. – Kevin Parker

The Future

It seems that sustainability and technology go hand-in-hand in reducing waste in the fashion industry. This research could possibly enable brands to reimagine how they use materials, fabrics, and textiles when putting on collections. Keratin waste is another environmental pollutant that is easily dumped and thrown out in several industries such as leather, and poultry farms.

On the bright side, the progress on 3D printing technology and the use of recycled materials has steadily been increasing throughout the industry especially for departments that require memory shape devices and garments like medical, aerospace, engineering, and more.